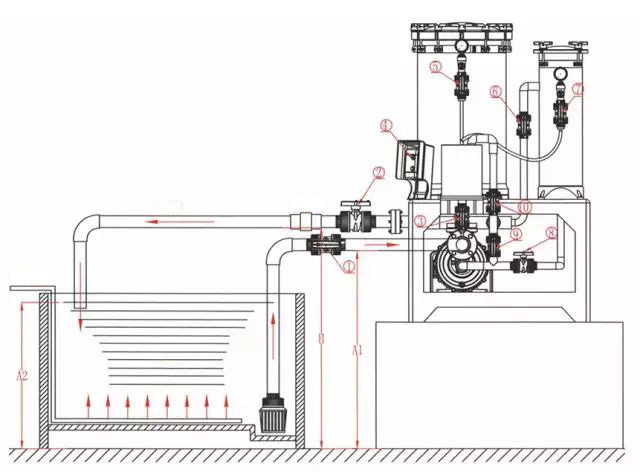

Step1: After the piping installation is complete, first close the outlet valve ②, to open the inlet valve 1 and close the other valve ①.

Step2: Open the lower end of the dosing tank valve ③, dosing liquid poured into the trough, the inner and the pump inlet conduit filled with liquid, and then close the valve ③.

Step3: Open the main filter barrel exhaust valve ⑤, turn on the power ④, the pump began to work.

Step4: When the main filter tub drain fluid without bubbles from the exhaust valve, close the vent valve ⑤.

Step5: Open the bypass switch valve inlet ⑥, so that liquid filtered into the activated carbon barrel.

Step6: Open the barrel of activated carbon exhaust valve ⑦, the liquid to be discharged without generating bubbles, close the valve ⑦.

Step7: Open the outlet valve bypass activated carbon barrel ⑧, until the liquid after its activated carbon adsorption of organic compounds barrel, from the activated carbon within the pump barrel outlet to the mouth into the circulation pump, and so on filtration.

Step8: Open the outlet valve ②, filter into the normal working condition.

Step9: If activated after the loss of adsorption, when activated carbon replacement, just close the ball valve and ball valve ⑥ to ⑧, filters can still work properly.

Step10: When the filtering effect to be detected, open the ball valve ⑩, the liquid can be detected.

Step11: When the filter effect is not ideal, it can open the valve ⑨, a second filter their liquid.