A: Features

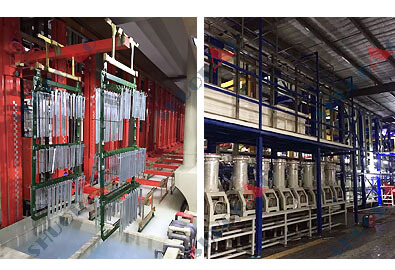

It adopt imported PLC and touched screen and rectifier (Import from Taiwan, Japan) can be adjusted. Also, it has memory function when power-off. Besides, it is fault detective. It can be full-automatic or semi-automatic and emergency manual operation.

It adopt imported PLC and touched screen and rectifier (Import from Taiwan, Japan) can be adjusted. Also, it has memory function when power-off. Besides, it is fault detective. It can be full-automatic or semi-automatic and emergency manual operation.- Plating equipment with digital display and real-time monitoring, flexible and easy manual operation, low noise, stable running and durable, safe and efficient.

- When replacing the product, no need to clean the material at the end, able to do anything to change the pre-treatment and electroplating time, the production line is still working properly, no stopping,no re-commissioning.

- We provide clean operating environment and not susceptible ambient air pollution.

- It is suitable for automobile parts, light and furniture, metalwork and electronic components.

- Electroplating equipment specifically designed according to user requirements, manufacturing.

B: Main peripheral equipment

1. Control System

- Main material of the control cabinet is Chinese standard Q235 after process of bending and pressing.

- PLC automatic programming system is imported from a highly reputational Japan /Germeny company with high stability and anti-interference ability.

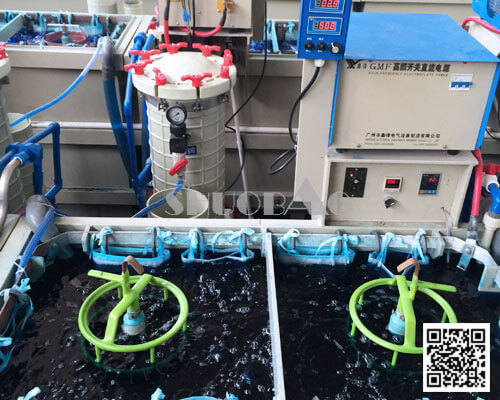

2. Rectifier

- To provide stable and proper current and voltage for the plating line, the current mode and voltage mode can be manually set

- Cable arrangement for secondary distribution box are all conformable to CNS standard.

- The main distribution box is within the scope of clients. (connected to non fuse switch of rectifier)

3. Filtration system

- Its purpose is to filter the chemical to remove the impurities, so that the coating would be smooth. The chemical will be mixed as well to ensure the temperature and density are evenly distributed, resulting in a homogenous plating coat.

4. Heating and cooling system

- In consideration of the equipment usage ratio and efficiency, all the materials of heating devices and heat sensors are all adapted to the relevant tank to avoid corrosion and damage.

C: Working Process

Alkaline degreasing → Spray chemical degreasing → Anode degreasing → Rinsing → Degreesing → Rinsing → Electrolytic pickling → Rinsing → Electrolytic activation → Neutralization → Anodic protection → Rinsing → Exchange → Semi-bright nickel plating → Recycle → Bright nickel plating → Recycle → Rinsing → Protection → Rinsing → Chrome plating → Recycle → Rinsing → Recovery after chrome plating → Recovery rinsing → Ddyer

We will be appreciate if you can provide the below details, so that we can make the exactly proposal for your reference.

- The capacity: xx/day, xx/month

- Weight and size for per product: ( it would be better if you could provide photos for us)

- Produce Cycle time:

- Workshop Dimension:

- Thickness of plating layer/lead time:

- Heater Time(2H 2.5H 3H 4H ):

- Equipment Model: (Automatic, semi-auto or manual):

D: How To Improve Your Competition Advantages

Effectively reduce plating costs.

- Labour costs. Solution: use highly automatic plating equipment, and use the new thought of “equipment instructing worker’s operation” to substitute the old thought “workers controlling equipment” because it is very difficult to control men. The “mechanical hand PLC intellectual control system” devised by SHUOBAO can greatly reduce labour costs.

- Plating solution. The plating solution is basically maintained by 1-2 workers in domestic plating plants ( it is easy to cause unnecessary addition of plating solution without control under scientific data.) . Solution: use the customized “measurable chemical addition system” to effectively control wastage of plating solution, reduces plating costs so that you can offer a lower plating quotation for clients.

- No-good rate of products. Besides the poor factors relating to plating materials and manual plating operation, the quality stalibity of plating equipment also greatly effect good rate. In the low-profit times, for keeping profit, the good rate should be

high ( the good rate of hardware products shall be more than 95%, and that of plastic products shall be over 90%). Stability of equipment refers to rationality and stability of electric system; advance and stability of PLC control; advance and validity of exhaust system; practicability and firmness of tand structure; stability and durability of perpheral configuration ( for example, rectifier, filter, pump, cooling water machine, oven, heating equipment, etc.). SHUOBAO tries its best to become an excellent player in this industry in the aspect of design, manufacture, etc.

high ( the good rate of hardware products shall be more than 95%, and that of plastic products shall be over 90%). Stability of equipment refers to rationality and stability of electric system; advance and stability of PLC control; advance and validity of exhaust system; practicability and firmness of tand structure; stability and durability of perpheral configuration ( for example, rectifier, filter, pump, cooling water machine, oven, heating equipment, etc.). SHUOBAO tries its best to become an excellent player in this industry in the aspect of design, manufacture, etc.

E: What We Can Support You

1. Fully proposal solution! Including

- Company Introduction. Our history and our Philosophy.

- Full process design based on your production capacity and item situation,and so on.

- drawing layout ,let you have whole idea about how to installation the equipments.

- Design outline which let you know all details of each part of plating line. especially the Electric part brand we choosed.

2. Technical support!

- Technical surpport before sales. any questions you can feel free to ask us.

- Our engineer will help provide full installation operation manual for you. even if you need them to help you in your factory.

3. Trainning provide. Our factory set up in plating industrial area. We can show you to many customer around us. From whom you can check how our equipment working there.