Model: KD-50SK-5

Material: PP/PVDF

Flow: 580 L/min

Heading: 31m

Voltage: 3Phase 220V/380V/415V

Temperature: 0-90 ℃

Delivery Date: About 1 week

Warranty Date: 1 year

- The pump’s body adopt FRPP, CFRPP, CPVC and PVDF material to getting with high temperature resistance and high corrosion resistance.

- Dry liquid seal design (1-10HP), to protect motor and bearing to be erosion by the chemical and to prolong it’s working life.

- It is widely applied for etching spray washing equipment, waste gas clean town, chilling system. It normally works with filter unit together.

- The pump design to work without water, it is available for idle running and avoid to any damage.

- If need pump work under high corrosion chemical, the titanium screw and EPOXY coated motor will be best options, it can enhance the corrosion resistance and service life.

- Our innovation to use FRPP as motor connecting seat’s material, it can maximum reduce acid corrosion and pump body weight compare to the traditional FC front motor bracket.

| Model | Diameter(mm) | Flow (L/min) |

Head (m) |

Power | Weight (kg) |

|||

|---|---|---|---|---|---|---|---|---|

| Inlet | Outlet | Phase | Poles | HP | ||||

| KD-40SK-1 | 50 | 40 | 280 | 13 | 3 | 2 | 1 | 29 |

| KD-40SK-2 | 50 | 40 | 400 | 22 | 3 | 2 | 2 | 38 |

| KD-40SK-3 | 50 | 40 | 450 | 26 | 3 | 2 | 3 | 41 |

| KD-50SK-3 | 65 | 50 | 530 | 23 | 3 | 2 | 3 | 41 |

| KD-50SK-5 | 65 | 50 | 580 | 36 | 3 | 2 | 5 | 55 |

| KD-65SK-5 | 80 | 65 | 550 | 29 | 3 | 2 | 5 | 55 |

| KD-65SK-7.5 | 80 | 65 | 780 | 36 | 3 | 2 | 7.5 | 55 |

| KD-65SK-10 | 80 | 65 | 780 | 39.5 | 3 | 2 | 10 | 106 |

| KD-40SP-3 | 50 | 40 | 400 | 19 | 3 | 2 | 3 | 41 |

| KD-50SP-3 | 65 | 50 | 500 | 32 | 3 | 2 | 3 | 41 |

| KD-50SP-5 | 65 | 50 | 560 | 32 | 3 | 2 | 5 | 55 |

| KD-65SP-5 | 80 | 65 | 520 | 25 | 3 | 2 | 5 | 55 |

| KD-65SP-7.5 | 80 | 65 | 750 | 35 | 3 | 2 | 7.5 | 95 |

| KD-65SP-10 | 80 | 65 | 750 | 38 | 3 | 2 | 10 | 106 |

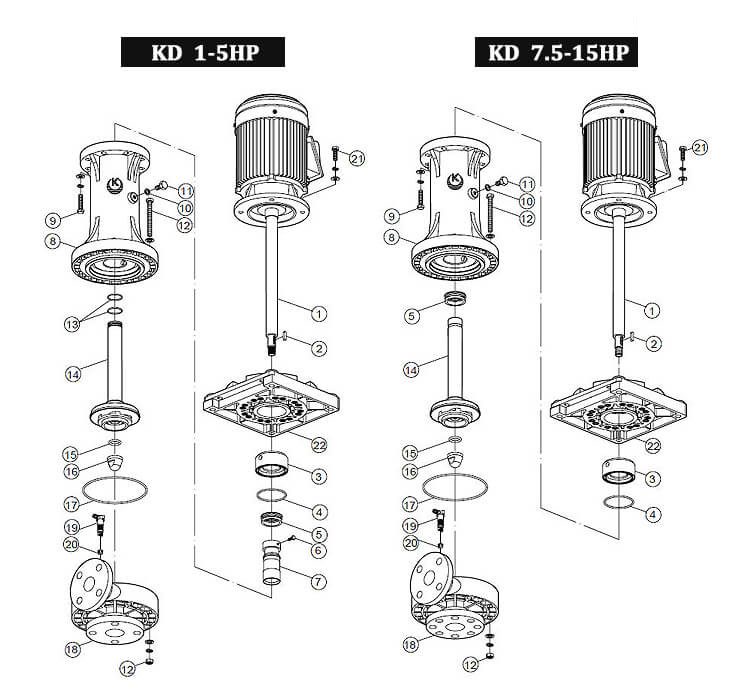

| No. | Description | Material | No. | Description | Material |

|---|---|---|---|---|---|

| 1 | Motor | FC / AL | 12 | Front Cover Screw | SUS |

| 2 | Shaft Key | SUS | 13 | Impeller O-ring | NBR/EPDM/VITON |

| 3 | Ceramic | FRPP/CFRPP/CPVC/PVDF | 14 | Impeller | FRPP/CFRPP/CPVC/PVDF |

| 4 | Vapor Seal O-ring | NBR/EPDM/VITON | 15 | Impeller Nut O-ring | NBR/EPDM/VITON |

| 5 | Vapor Seal | NBR/EPDM/VITON | 16 | Impeller Nut | FRPP/CFRPP/CPVC/PVDF |

| 6 | Shaft Sleeve Screw | SUS | 17 | Front O-ring | NBR/EPDM/VITON |

| 7 | Shaft Sleeve | FRPP/CFRPP/CPVC/PVDF | 18 | Front Cover | FRPP/CFRPP/CPVC/PVDF |

| 8 | Main Body | FRPP/CFRPP/CPVC/PVDF | 19 | Air Release Valve | FRPP/CFRPP/CPVC/PVDF |

| 9 | Main Body Screw | SUS | 20 | Air Release Valve Packing | NBR/EPDM/VITON |

| 10 | Release Screw O-ring | NBR/EPDM/VITON | 21 | Motor Screw | SUS |

| 11 | Release Screw | FRPP/CFRPP/CPVC/PVDF | 22 | Motor Spacer | FRPP |