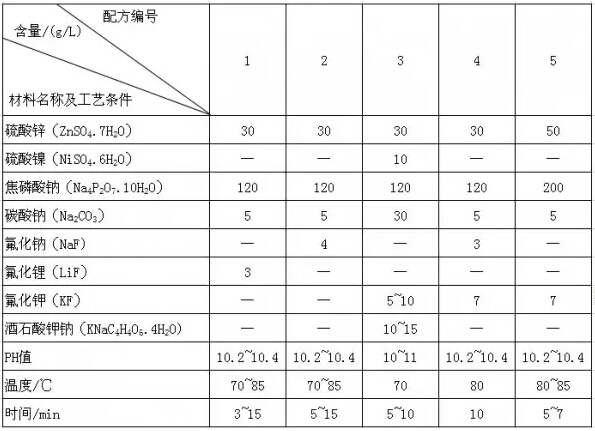

Dip Zinc is the most commonly used and effective method of magnesium alloy plating. Pretreatment degreasing, etching, and activation of the magnesium alloy workpiece for chemical zinc removal on a layer of zinc. The change in the composition and process conditions of the zinc solution will affect the thickness and density of the zinc impregnated layer, which means that it will directly affect the quality of the subsequent coating. Magnesium alloy dip zinc solution formula and process conditions in Table 1-1.

Preparation method of zinc leaching solution

The zinc sulfate is dissolved in hot water at 70 ° C, then sodium pyrophosphate is added in portions, and the white precipitate is completely dissolved while stirring, and the fluoride and sodium carbonate are added. Stirring is carried out and the mixture is thoroughly dissolved and tested Adjust the PH value.

(Note: If the addition of lithium fluoride, because of its low solubility, up to 3g / L has reached a saturated state, the excess lithium fluoride can be installed in the corrosion of the bag, as the dip zinc solution.)

Control of dip zinc solution

The concentration of zinc in the zinc solution is preferably controlled in the range of 6g / L ~ 11g / L, and the concentration of P2O74- is controlled to keep the ratio between the two.

The temperature of the zinc solution is generally controlled at 70 ℃ ~ 80 ℃ as well. Zinc extraction time is too short, not dense zinc layer, zinc time is too long, zinc layer is too thick, loose, zinc time is generally controlled in 5min ~ 15min, zinc layer thickness of 2.5μm ~ 2.8μm as well.

Secondary zinc plating process

The zinc layer after the first zinc leaching in the 20% to 30% HNO3 solution, the withdrawal of zinc or fluoride in the activation of the reactor to remove the zinc layer, the operation time is about 30s, until the zinc layer is completely removed after washing The second zinc-impregnated zinc layer is more homogeneous and can enhance the binding force between the magnesium alloy substrate and the subsequent coating.