1. Plating Area calculation of workpiece

It is difficult to estimate the surface area of the workpiece in each barrel, but rolling plating items are relatively stable, if can make a table, the quantity and weight of each batch of different forms of workpiece, the total area of valuation and the distribution of the current intensity and the quality record is available after plating on the same or similar forms of products as a distribution current basis.

Some factory is according to barrel the weight of the workpiece to the distribution of current intensity, obviously this is not correct, because the thickness of workpiece to a certain weight within the scope of the surface area is not the same. In addition, the temperature of the plating solution, the change of the concentration, the amount of the rolling element and so on are the important basis of the distribution current, and should be considered.

In addition to the basis of the above, can also calculate the area of a workpiece, and then multiplied by the total number of pieces of the workpiece, when the weight of the concept of charging by weight, can calculate it first.

2. How to improve the utilization rate of the rolling bath

Normally barrel plating workshop is full of workload,the tank volume is relatively small, the volume of a solution of a high current density, fast solution consumption, the proportion of each component is easy due to be imbalance, the pretreatment of workpiece surface is difficult to purify, dirt easily into the problems such as the existence of the plating bath, and plating solution needs to be adjusted frequently, supplement purification and processing. It takes time, such as a backup solution to solve this problem, the failure to suck out the contaminated solution, injection standby solution can continue to work, and then adjust the solution out of the replacement, supplement and purification treatment, as the next round of preparation with solution to replace.

3. Improvement of barrel plating cleaning

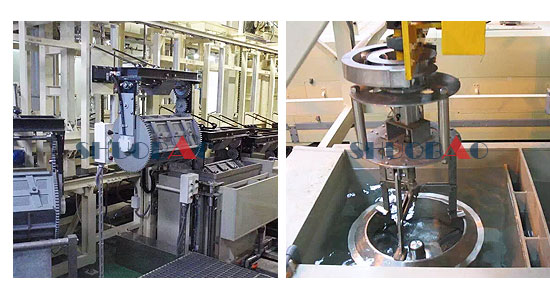

Barrel plating with a large amount output, in order to improve the cleaning effect, the first to reduce the amount of output. When the solution tank above the drum in the water retention is an effective method. Because the components may contain water, even after the lift roller rotation, in order to make drops of water, so when the rotating drum is very necessary.

The drum is rotated after the method mentioned in the upper part of a rack driving roller, an occlusion type gear and rack. The drum is rotated due to the limited length of the drum can’t turn a circle, water flow without stopping, the effect is not good enough. Another method is to install an electric motor speed reducer, when the roller lift gear and motor gear meshing gear bite to make the drum rotation, this approach has good results.

Some barrel plating line, a blower is arranged in the lane on the drum by filed after the wind blew the solution inside the drum, this effect is good, but the equipment is more complicated.

In addition, the drum washing, the parts in the drum, the water into the drum has a certain degree of difficulty. In order to overcome this problem, some plating line there is a drum mechanism, brought out a pipe connected with the water pipe, cleaning water directly into the cylinder so that the cleaning effect is good.